Rigmond Quantrial

Rigmond Quantrial

Rigmond Quantrial

Rigmond Quantrial

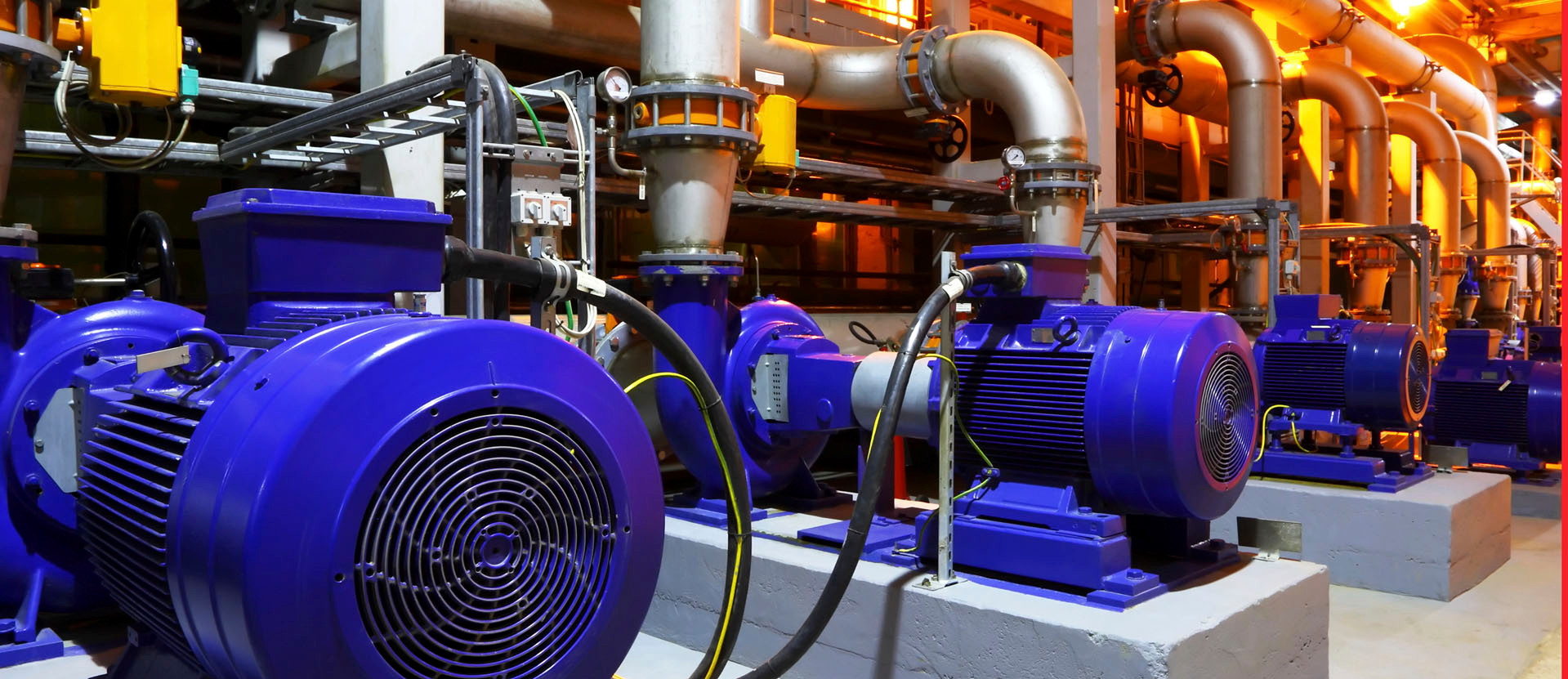

Industrial automation is an area we excel in and we provide the best services at a global standard. Our brand is known for its reliable and effective planning and we have got plenty experience in doing many overseas project. We are the leaders of Industrial automation in the international market.

Our firm does business on contract basis. Planning and professionalism are the fundamental tools that we use to create and uphold premium quality in our services. We use computerized control systems in designing and executing various facilities like industrial machinery, manufacturing lines, process environment, etc. so that the automated system bring maximum efficiency into operations. Our services include SCADA Automation services, Panel Construction Services, Turnkey PLC Automation, Power Panel Installation and Electrical Contracting Services.

We have been able to complete many high profile overseas projects successfully and have undertaken many projects in electrical design, Supervisory Control & Data Acquisition (SCADA), PLC or DCS Control, and Human Machine Interface (HMI). We also have got good experience in machine vision implementation, robot integration, instrumentation calibration and tuning. All these exposure and experience is the reason for the demand for our services throughout the globe.

Our commitment to a project being by Adhering ourselves & demanding our Suppliers to maintain the highest manufacturing standards.

At Rigmond Quantrial Automation, we are striving towards a single goal to improve our customer’s productivity with the best industrial automation solutions, reliability and services in India.

At Rigmond Quatrial Industrial Automation, we believe that success in a highly competitive market depends on continuous support of products supplied that meet the needs of our customers in India markets. Our goal is to design and manufacture products that are simple to install, easy to use and that gives you the flexibility to choose your level of investment to increase your production.

Our solution will support Obtain real-time and predictive performance measures from plant operational efficiencies Benefits :

We offer a broad range of integrated control and information solutions that are fully tested and field proven to meet or exceed solar industry requirements, including :

A chemical plant is a facility that manufactures chemicals. It is an industrial plant where chemicals are produced on a large scale basis through process such as transformation, separation, etc. These facilities have custom made apparatus and equipments that helps in the manufacturing process. Thus it is an automated facility.

These chemicals are mainly used, partially or fully, as drugs, polymers, for refineries, etc. There are various industries that use such plants. Some are pharmaceuticals, reactors, etc.

Pick and place is a type of equipment designed to move and place delicate items between short distances. Safety and accuracy are the two main focuses of this device. There many areas where this device is used. Some are in industries like glass making industry, bottle making industry, paint manufacturing industries, etc. Their main works include loading, unloading, moving and placing. The device is used in areas like manufacturing, warehousing and experimenting.

Cement is substance used for binding rocks, bricks, etc. Cement industry manufactures and markets cement which is used for construction purposes.

Paper is a material made from moist fibres which is used for writing, drawing, printing, etc. The paper industry makes papers from derivatives of cellulose pulp such as wood, rags, grasses, etc. These companies make, move and market paper.

Pulp is a raw material for making paper. It is a kind of fibrous material made from wood, grass, etc. through mechanical or chemical processes.

Like other industries automating the functions will enable the Manufacturers to minimise cost and effort, but maximise profit and output.

Welding is a sculptural process for joining metals or thermoplastics. It is a two stage process involving melting and cooling. The operation uses coalescence. Heat is the main character in the process. The scope and applications of welding are large. It is used for industrial purposes, for construction, aerospace, tubing, instrumentation, etc.

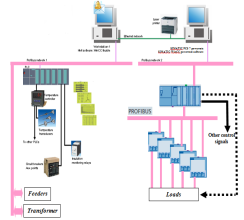

We provide SCADA Software for best supervision related tasks for our clients. SCADA or supervisory control and data acquisition is a software program for industrial control system. Its basic functions are monitoring and controlling processors. It is used as human machine inter-automation service. It is very helpful in controlling activities from a central point or a control room. This is an area where we had the most clients. They were more than satisfied with our services.

PLC refers to Program Logic Control. A PLC is used to automate devices that do electromechanical processes. PLC controllers help to automate various operations in industries that deal with electromechanical works. We provide various types of PLCs such as the turnkey PLC automations services. It belongs to our electrical contracting wing. These are highly appreciated by the clients for its high reliability and quality. Our services in this wing include testing, supplying, and installation. All these services are available at unbeatable- cheap prices. We also provide customized services for our clients depending on their needs and specifications.

DCS control panel is another electrical contracting work that we provide. Our services are known for its timely execution and accuracy. Such automation services of us are of high demand in the market. These too are available for cheap prices.

It is the virtual place where the interaction between humans and machines occurs. Communication between man and machine is directly related with the effectiveness of the operation is intended to be a controlling feature. We are providing HMI devices for automation services and control systems. The products and services are of great demand in the market due its superior quality and cheapness. Moreover we deliver results within the timeframe. Our team comprises of top professionals who has more than sufficient experience in the field. Thus the efficiency of such automation services remains unparallel.

Substation Control & Relay Panels

Generator Control & Relay Panels

Synchronising Panels(PLC & Relay based)

AMF Panels

Bus Ducts

Control Centers

PLC Based Control Panels

AC Drives / Softstarter Panels

SCADA System

Capacitor Bank Control & Relay Panels

Instrumentation Panels

Load Management / Power Plant Automation Panels

Local Control stations

Power Distribution Boards

Grid Islanding & Load Shedding Panels

LAVT / NGTR Panels

-Aristotle

Rigmond Quantrial’s business values and shared standards are built around creating an environment of teamwork, fairness, security, integrity, dignity and respect, benefiting not only Clients, Stakeholders, Employees & Peers but also influencing the business environment we operate in. It is our firm belief that these objectives can only be achieved through mutual respect and cooperation.

45, NRI Nest,

Ashok Nandhavanam

Melmanambedu

Vellavedu

Chennai - 600124

info@rigmondquantrial.com